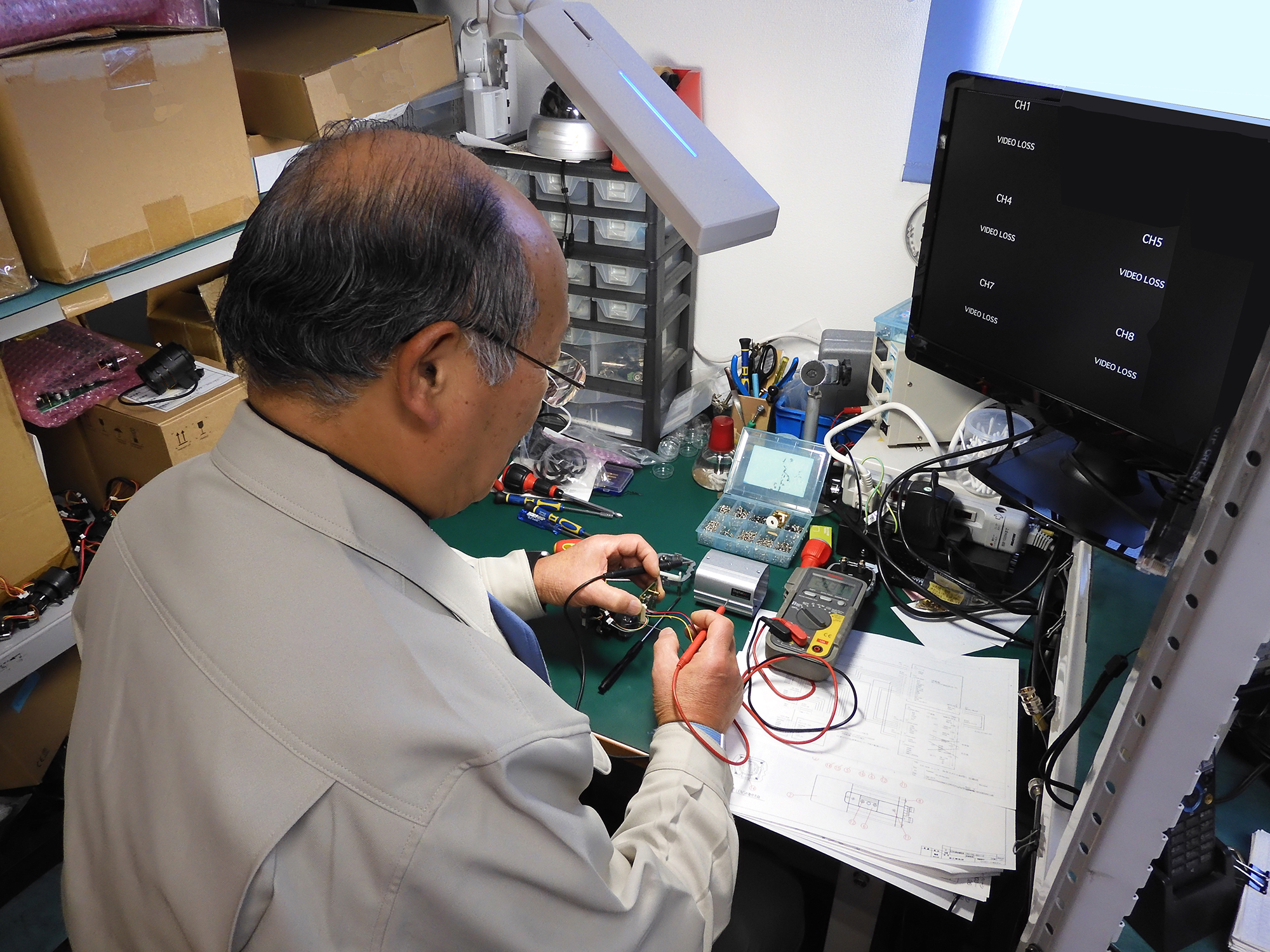

Features of Tescom Japan

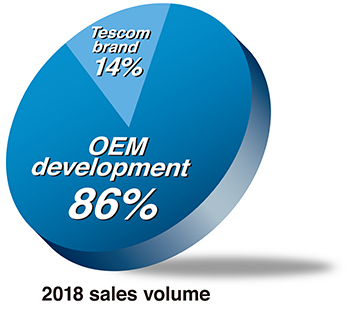

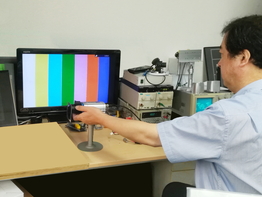

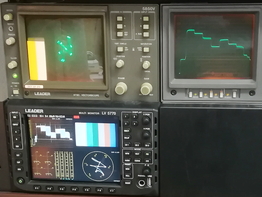

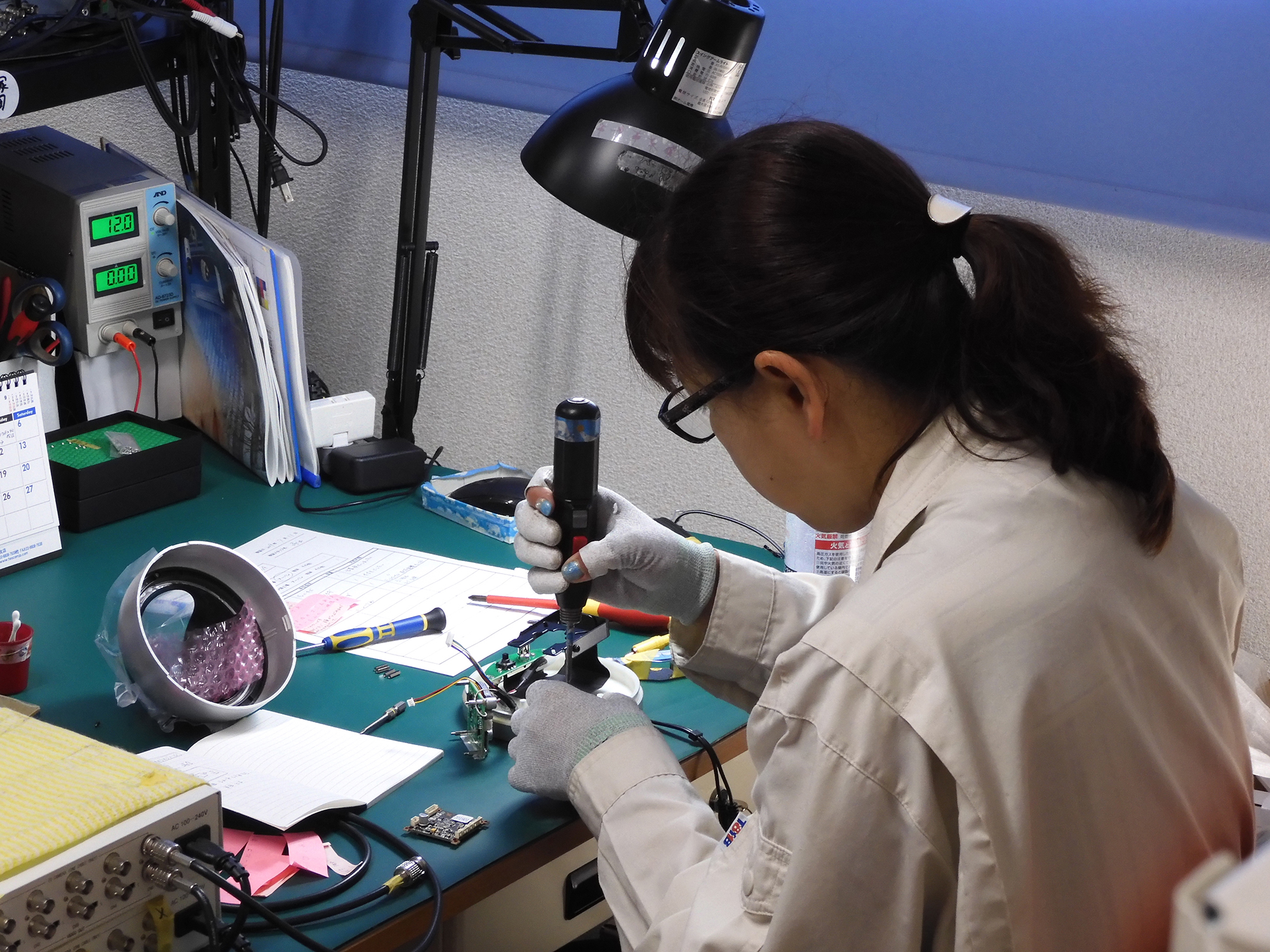

In 2000, we started security business as a manufacturer of video equipment, supplying OEM and ODM to major electronics manufacturers, security equipment manufacturers, and security companies. We have our own professional R&D team and are highly evaluated for technical and development capabilities. Currently, our main business is OEM development and manufacturing, which account for about 86% in sales volume, and TESCOM brand sales only occupy 14% (2018 results).